HRZL-LG high-rise building feed water pump (vertical multistage centrifugal pump)

Flow range : 3.0-50m³/h

Head : 20-150m

...

Chat Now >>

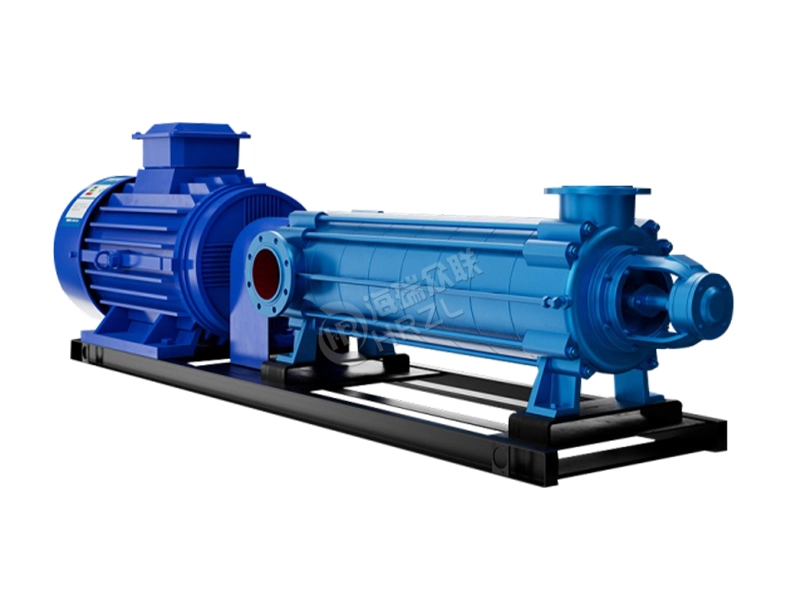

HRZL-GC/GCL horizontal multi-stage boiler feed water pump

Flow range : 10-98m³/h (customizable)

Head : 90-1104m (customizable)

...

Chat Now >>

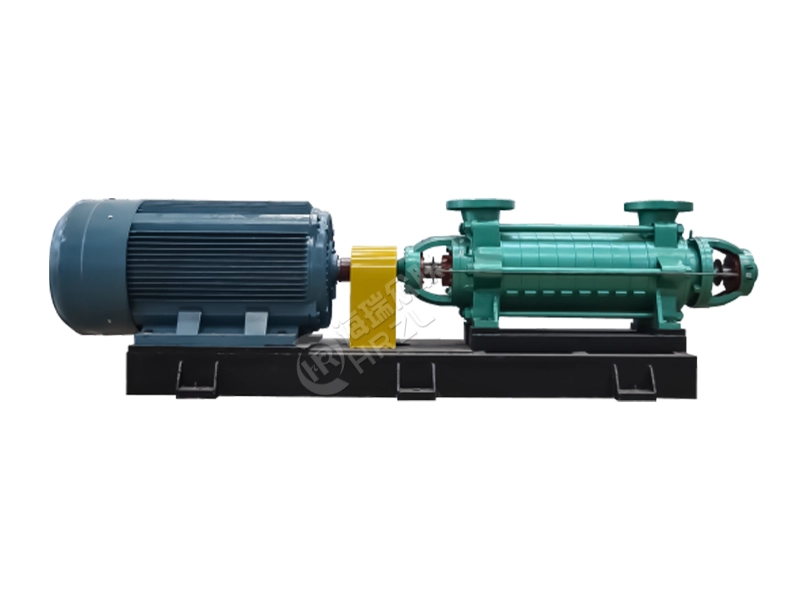

HRZL-D/MD Abrasion-proof multistage centrifugal pump

Flow range : 35-1000m³/h

Head : 22-650m

...

Chat Now >>

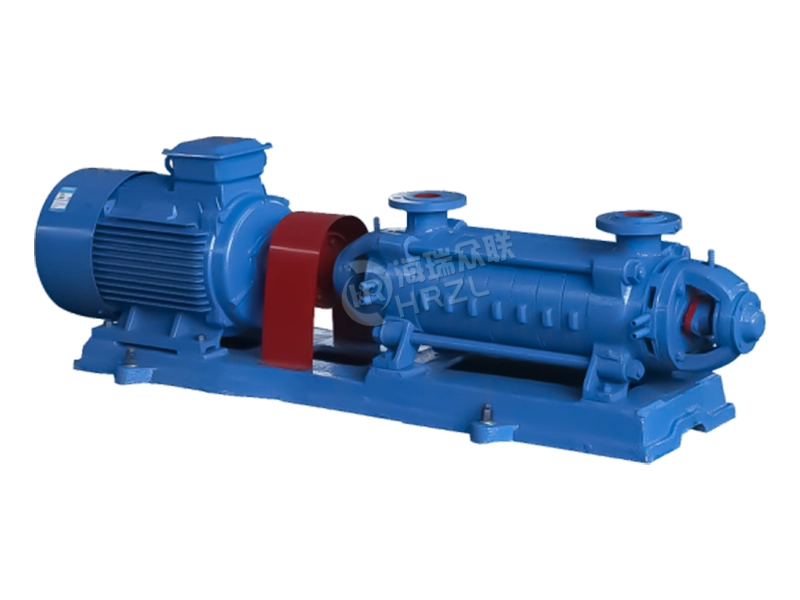

HRZL-DG horizontal multi-stage clear water centrifugal pump

Flow range : 10-98m³/h (customizable)

Head : 90-1104m (customizable)

...

Chat Now >>

Stable pressure High head

By changing the number of pump stages to meet different requirements the same pressure can be maintained steadily for a long time during the boosting process.

Multistage impeller

Multiple impellers are connected in series to achieve the effect of high head pressurisation and dynamic balancing tests are carried out to ensure the stability of the pump.

Tight shaft seal

The use of packing seals or mechanical seals do not allow the flow of water out of the pump and do not allow the entry of air outside the pump.

Wear-resistant shafts

Low friction resistance, high heat dissipation, high temperature resistance, high durability, no need for frequent maintenance.

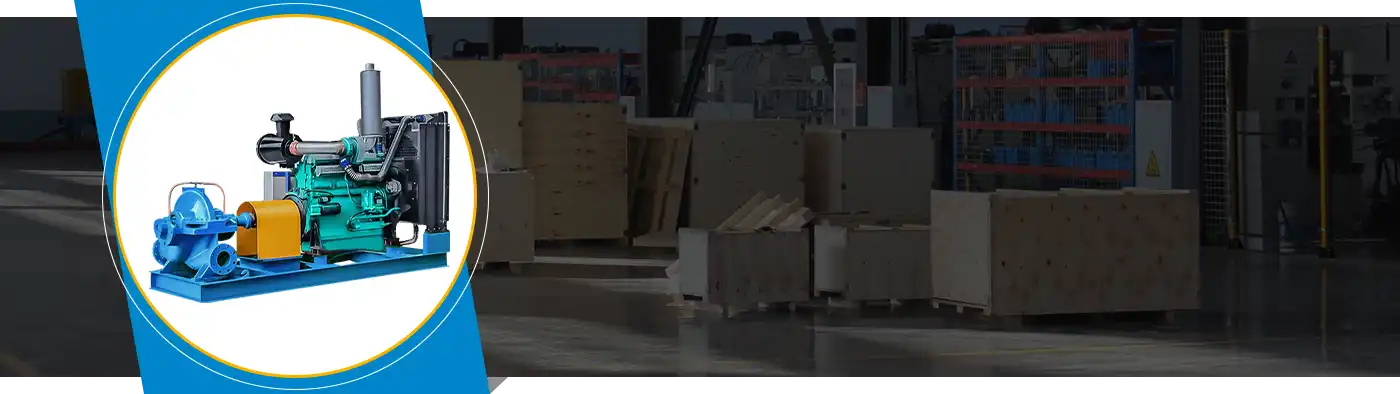

As an efficient, reliable and adaptable pump equipment, diesel engine pumps have quite a wide range of applications. The following are the main application areas of diesel engine pumps: agricultural irrigation, industrial production, building construction, urban water supply, emergency rescue, sewage treatment, fire-fighting systems, ships and trains, generator sets.

Multi-stage pumps, as a kind of centrifugal pumps with two or more impellers, multi-stage pumps are widely used in industry, agriculture, construction, municipal and other fields due to their advantages of high head, high efficiency and energy saving, stable operation, adaptability, compact structure, easy adjustment and long service life.

Double suction pumps play an important role in liquid transfer and circulation systems due to their unique structural design and excellent performance advantages. Also need to pay attention to its possible easy to clog, high maintenance costs and higher installation requirements, in the selection and use of the specific working environment and needs to be weighed!

As a device that can convert mechanical energy into hydraulic energy, single-stage pumps have a wide range of application scenarios in many fields due to their simple structure, high efficiency and large flow rate.

Stainless steel water pumps have the advantages of high efficiency, lightweight, stability and versatility, which can meet different conditions of use and needs. When choosing stainless steel water pumps, you need to weigh the specific application scenarios and needs, and choose the most suitable product.

As an efficient, reliable and adaptable pump equipment, diesel engine pumps have quite a wide range of applications. The following are the main application areas of diesel engine pumps: agricultural irrigation, industrial production, building construction, urban water supply, emergency rescue, sewage treatment, fire-fighting systems, ships and trains, generator sets.

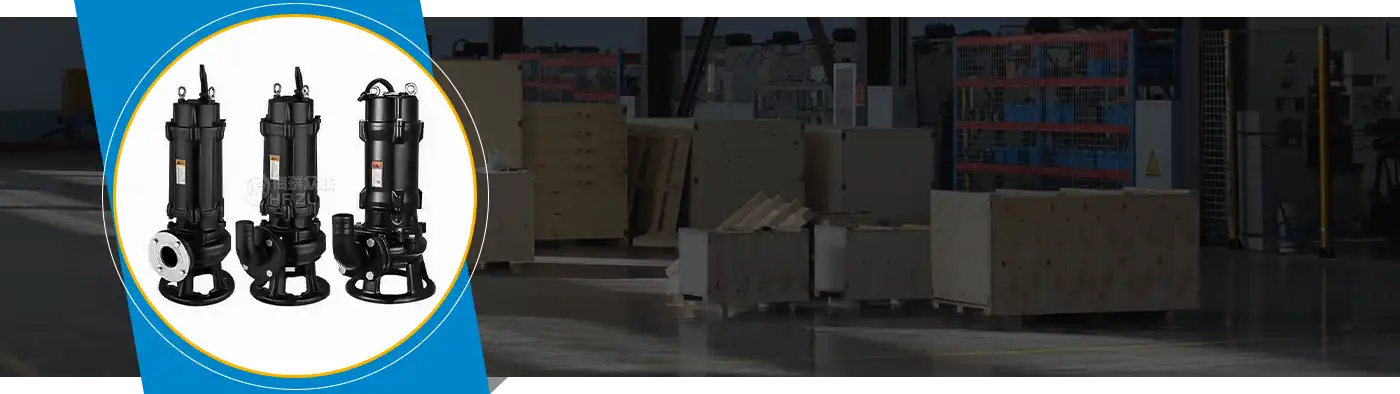

A sewage pump is a pump specially designed to handle and discharge liquids containing solid particles, fibrous materials and other impurities. It plays an important role in a variety of application scenarios, especially in the fields of sewage treatment, building drainage, municipal engineering and industrial discharges

With its advantages of high efficiency, stability and corrosion resistance, long shaft pumps are widely used in many fields, such as municipal, industrial, agricultural, water conservancy, mining, shipping and so on. With the continuous progress of technology and the continuous development of the market, the application range of long-shaft pumps will be further expanded.