Introduction:

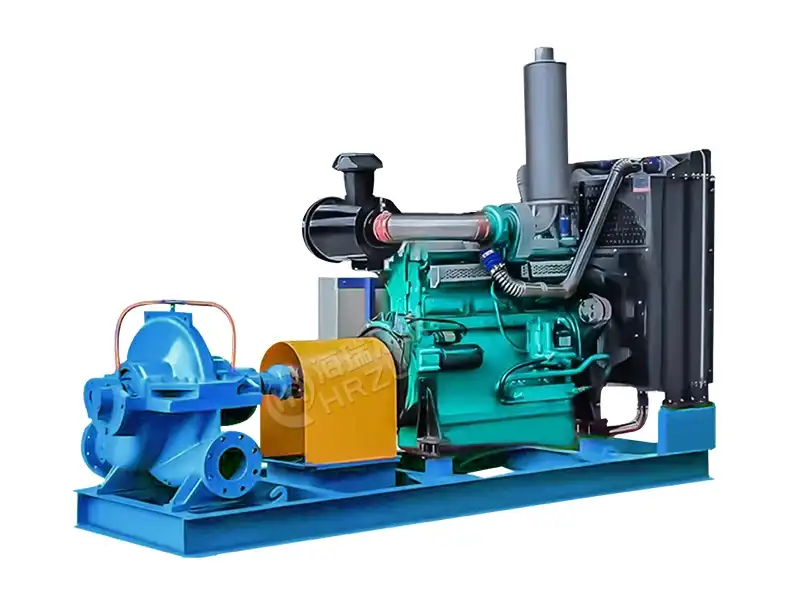

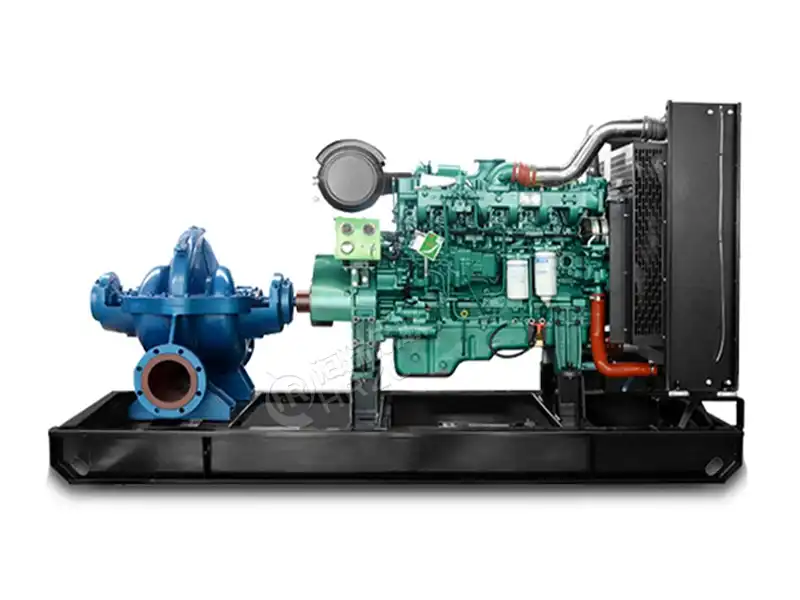

The HRZL-C/SH diesel engine double-suction split pump is engineered as a single-stage, double-suction, horizontal split centrifugal pump. It is particularly suitable for the transportation of clean water and non-corrosive liquids, accommodating a maximum medium temperature of 80°C. When the bearing housing is provided with cooling water, it can manage hot water temperatures reaching up to 130°C. By modifying the materials utilized for the sealing ring, shaft sleeve, and impeller, the pump is capable of handling muddy water containing sand. The inlet pressure can be optimized by selecting various materials for the pressure-bearing components. This pump is ideally suited for use in factories, mining operations, urban environments, power generation facilities, water supply systems, agricultural drainage and irrigation, as well as a range of water conservation initiatives. Furthermore, pumps fitted with copper impellers and copper sealing rings can be tailored to meet specific user requirements for the transfer of refined oil and similar substances.

Features:

Axial force equilibrium

Low operational failure rate

Smooth functioning with minimal noise

Optional self-priming feature

The design showcases a linear configuration, offering an attractive appearance, strong stability, and ease of installation. The advanced design of the double-suction impeller effectively reduces axial force to a minimum and features a blade design that provides excellent hydraulic performance. Following precision casting, both the internal surface of the pump casing and the impeller are exceptionally smooth, leading to remarkable anti-cavitation properties and high efficiency.

Customized solutions:

HRZL is willing to customize the pump functions based on your actual needs, striving to satisfy every customer. Our quality assurance department strictly implements the quality inspection process to ensure the reliability of the pump.

Related Cases:

Ethiopia power station

Egypt water conservancy project

Saudi Arabia new energy company